LOADING EQUIPMENT

LOADING EQUIPMENT

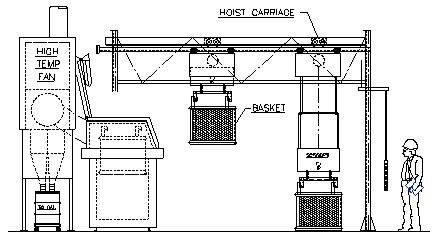

The Pyro-Strip fluidized bed can be equipped with the innovative Tilt-Loader or the conventional Bridge Crane loader with the following features:

- ELECTRIC CHAIN HOIST ASSEMBLY

- SCISSORS LIFT ASSEMBLY

- WIRELESS PENDANT CONTROL

- ULTRA-FAST LOADING

- BASKET VIBRATOR

INTEGRAL TILT-LOADER SYSTEM

STAND-ALONE TILT-LOADER WITH SCISSORS LIFT:

Free standing oscillating device for loading the Basket into the Tank. The Tilt-Loader is activated by multiple air cylinders that Latch the basket and swigs the Hoist and Scissors in and out of the tank area. The loader features bolted construction and welded upper frame for the scissors and hoist.PRODUCT BASKETS

The Baskets are fabricated with a structural steel frame and steel perforated metal envelope designed for heavy loads and constant use. The unique basket construction eliminates the accumulation of media in the basket. The frame has a special load bar double hook assembly for the lifting of the load in a stable non-shifting manner. The basket design can be modified to accommodate the needs of the product as required by the project.

CYCLONE SYSTEM

INTEGRATED CYCLONE AND FAN ASSEMBLY:

The Cyclone is completely shop assembled and insulated. The unit extracts process heat from the fluidized bed and mixed with cool plant air and drawn through the high efficiency Multi-Cyclones where the fine particulate are separated from the airstream and collected in the waste drum for disposal.- PRECISION AIRFLOW CONTROL

- ULTRA-FINE PARCTICULATE EXTRACTION

- INTEGRAL MINI-CYCLONE ASSEMBLY

- INSULATED CYCLONE PLENUM

- INTEGRAL FAN DESIGN

- TEMPERATURE MONITORING

- DRUM WASTE CONTAINER

SECONDARY POST COMBUSTION AFTER-BURNER

The Pyro-Strip fluidized bed can be equipped with the optional Post Combustion After-Burner to further combust exhaust gasses and comply with Local Jurisdictions that interpret NFPA, EPA and OSHA regulations.

- SPECIAL DESIGN AFTER-BURNER ASSEMBLY

- VOLUME FLOW CONTROL POST-COMBUSTION CHAMBER

- PROGRAMMED BURNER OPERATION

- CONSISTANT EMMISSION RESULTS

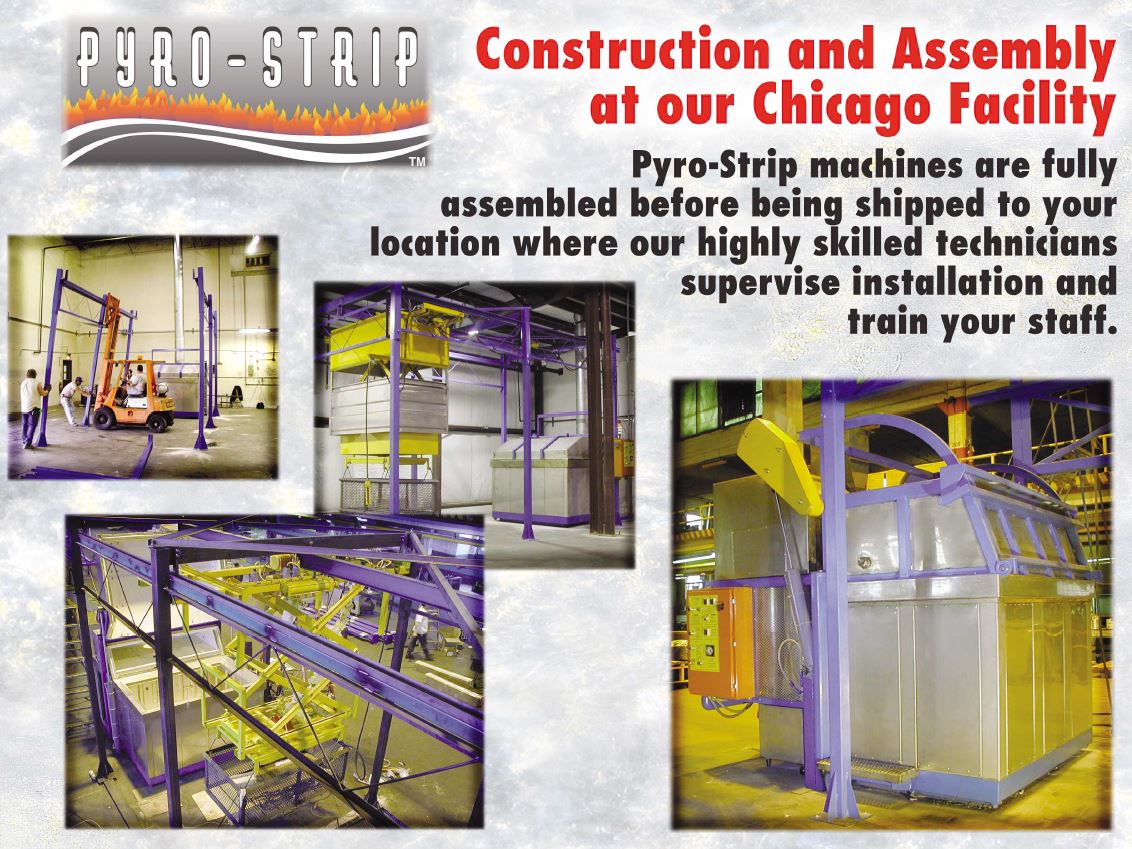

PRODUCT CUSTOMIZATION

All of our PYRO-STRIP™ systems are customizable, from the dimensions to the type of loading and unloading process you require. Our engineers will walk you through the basic model and will help you determine the best design for your company based on financial resources, material being stripped, local enviormental laws and regulations as well as the location for the pyro-strip system.