PROCESS

THE FLUIDIZED BED PROCESS

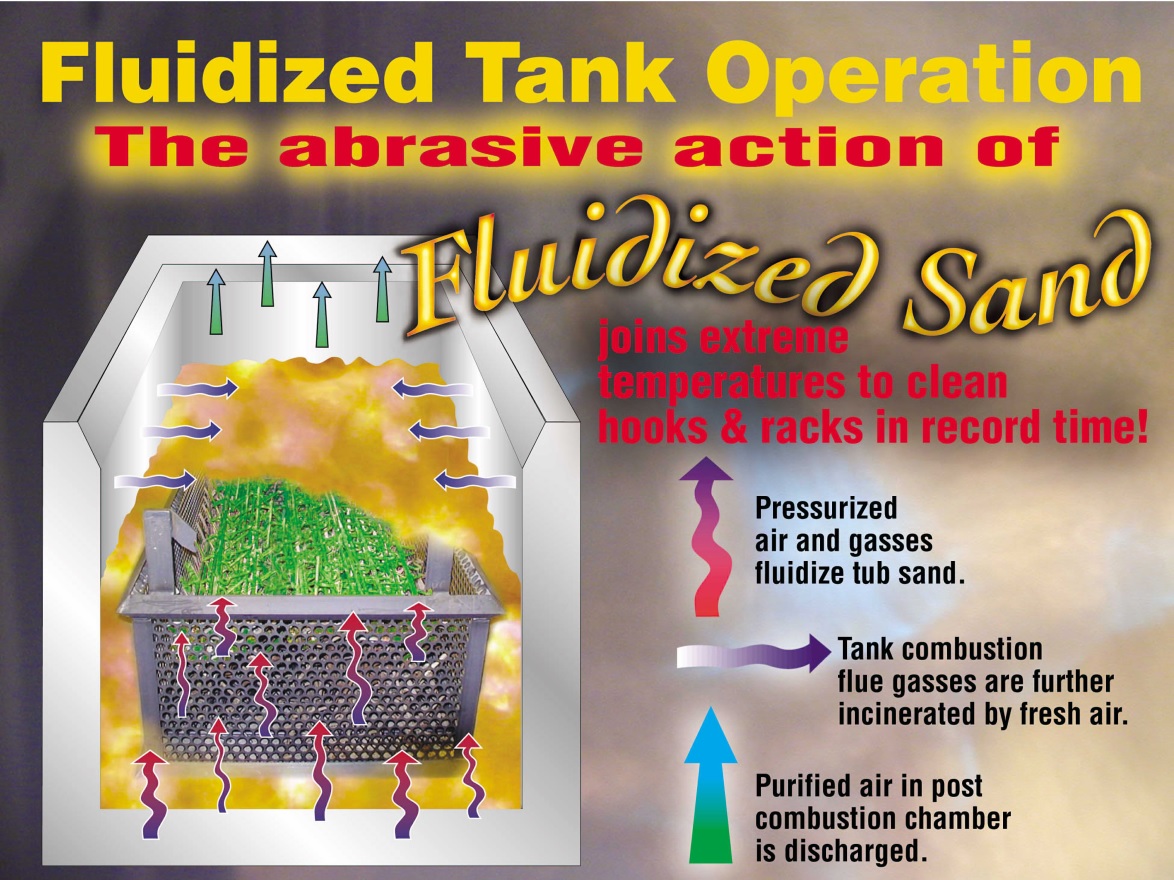

The fixtures to be cleaned are loaded into the included load basket. The hood is raised and the basket and parts are then loaded into the preheated fluidized tank. The heated sand begins a thermal process where paint, powder coating or other organic compounds to be cleaned are turned into a gas. This gas percolates through the fluidized sand and is ignited at the top of the sand along with natural gas or propane used to directly heat the sand. The flame on top of the sand is an afterburner zone where thermal oxidation destructs the organic gasses. After the organics are processed the mechanical cleaning cycle begins. Ash is removed from the fixture from the washing action of the fluidized sand. The negative pressure of the cyclone fan draws the ash and sand fines from the tank into the high efficiency cyclone where particulate matter is removed before process gasses are exhausted out the stack. Removed ash and sand fines are collected in a drum receptacle beneath the cyclone for disposal.

The fixtures to be cleaned are loaded into the included load basket. The hood is raised and the basket and parts are then loaded into the preheated fluidized tank. The heated sand begins a thermal process where paint, powder coating or other organic compounds to be cleaned are turned into a gas. This gas percolates through the fluidized sand and is ignited at the top of the sand along with natural gas or propane used to directly heat the sand. The flame on top of the sand is an afterburner zone where thermal oxidation destructs the organic gasses. After the organics are processed the mechanical cleaning cycle begins. Ash is removed from the fixture from the washing action of the fluidized sand. The negative pressure of the cyclone fan draws the ash and sand fines from the tank into the high efficiency cyclone where particulate matter is removed before process gasses are exhausted out the stack. Removed ash and sand fines are collected in a drum receptacle beneath the cyclone for disposal.

After a short cleaning cycle, usually 40 to 60 minutes, the basket is removed out of the machine and another basket of fixtures can be loaded immediately.

The Pyro-Strip fluidized bed is an economical, fast and thorough cleaning system. The sand temperature is homogeneous throughout the bed and can be precisely controlled to assure that fixtures do not become annealed. Organics are destructed without the need for disposal of hazardous waste.

The Pyro-Strip fluidized bed can also be outfitted with the optional After-Burner to further combust exhaust gasses and comply with Local Jurisdictions that interpret NFPA, EPA and OSHA regulations.